Since I am replacing the ICS M4 S-System’s top gearbox shell with a Retro Arms upper shell, I thought I would take this opportunity to try out a different piston as well. This time, I will be taking a look at the Lonex Red Extreme Toughness Piston. The label says it is made out of polycarbonate, but most comments online that I could find states that it is made of tougher material. I’m always on the look out for a nice AEG piston, and I think this is one of those.

The airsoft piston is a part that can require a lot of attention. Speed and power applications require different approaches on how to handle this part for an intended effect. The Lonex Red Extreme Toughness Piston has a plastic body construction with reinforced steel tooth rack. The plastic construction gives the user the option to drill out the body with less effort for a slight mass adjustment. Running plastic piston bodies can also be used as a safety measure by engineering a failure point in the gearbox on a part that is easier and less costly to repair or replace.

Tooth Rack & AOE

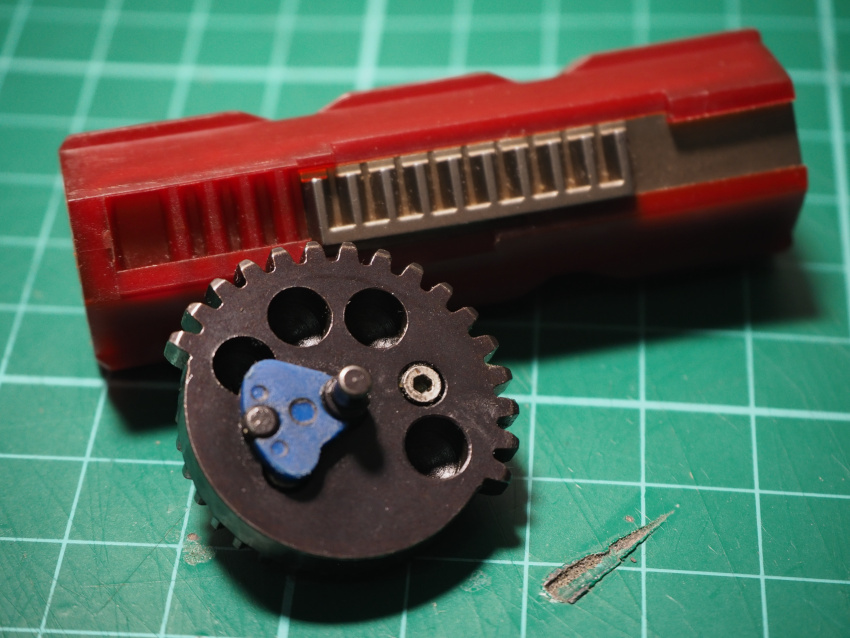

Hybrid 5 Plastic & 10 Steel Tooth Rack

The first five plastic teeth of the piston is part of the body’s molding. It is followed by a steel tooth rack with ten teeth. I prefer this style over a predominantly plastic or metal tooth rack where there is only 1 metal tooth or the whole rack is metal.

Reinforced Teeth

By design the teeth are bridged. On the body itself the plastic teeth are connected to each other on both sides. The steel ten-tooth rack only bridges the teeth together on one side. Nevertheless, forming the teeth together helps share the load to lessen the chance an individual tooth prematurely snaps off. However this does not protect the tooth from being worn away by normal operation.

Deleted 2nd Plastic Tooth

The second tooth is omitted leaving only five plastic teeth during the initial engagement of the sector gear. Getting rid of the second tooth on the rack is common practice to give the sector gear pick-up tooth clearance when adjusting the angle of engagement between these two parts. Most stock and some aftermarket pistons will leave the 2nd tooth for you to remove on your own. Here it is removed by design.

Clearances

Piston Guide Rails

The guide rails on the piston have lubricating channels to help keep light grease or oil to keep them lubricated. The inner part of the rails are actually raised higher compared to the outer which follow the gearbox wall curvature and help keep contact to a minimum. Even on the stock ICS upper gearbox shell the Lonex Red Extreme Toughness piston has ample clearance all around and glides smoothly along the tracks.

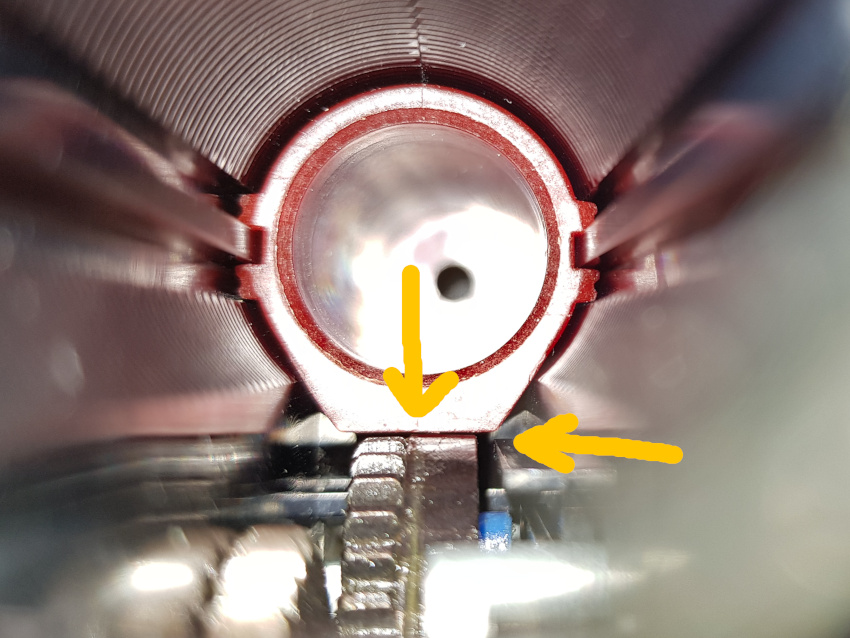

SHS 16:1 Sector Gear Clearance

One place the piston can bind is on the sector gear, where the initial pickup tooth is low enough to collide against the toothless portion of the sector gear as it is pulled back. The Lonex Red Piston does well here with fractions of a millimeter of space available between the piston and gear. This ensures that this Lonex piston clears the sector gear properly while providing good contact for the pick-up teeth to catch on.

Meshing

SHS 16:1 Sector Gear Teeth Upward Vector

Another concern I had is the transition of the sector gear teeth running between the plastic teeth to the metal teeth. This difference can sometimes cause the sector gear tooth to bind in transition and push the piston up against the gearbox or cylinder. The worst part is that it can cause a kink in the cycle that wears down both the piston and the gears.

On the stock ICS gearbox shell, the Lonex red piston does not experience any obstacles. On the Retro Arms shell however, the piston slightly pushes upwards a small amount as the sector gear teeth move along between the plastic and metal teeth. Thankfully the amount it rises is very minor compared to problematic ones I’ve encountered in the past. Although the slight change in transition is present, it will pose little risk of binding the piston mid-cycle.

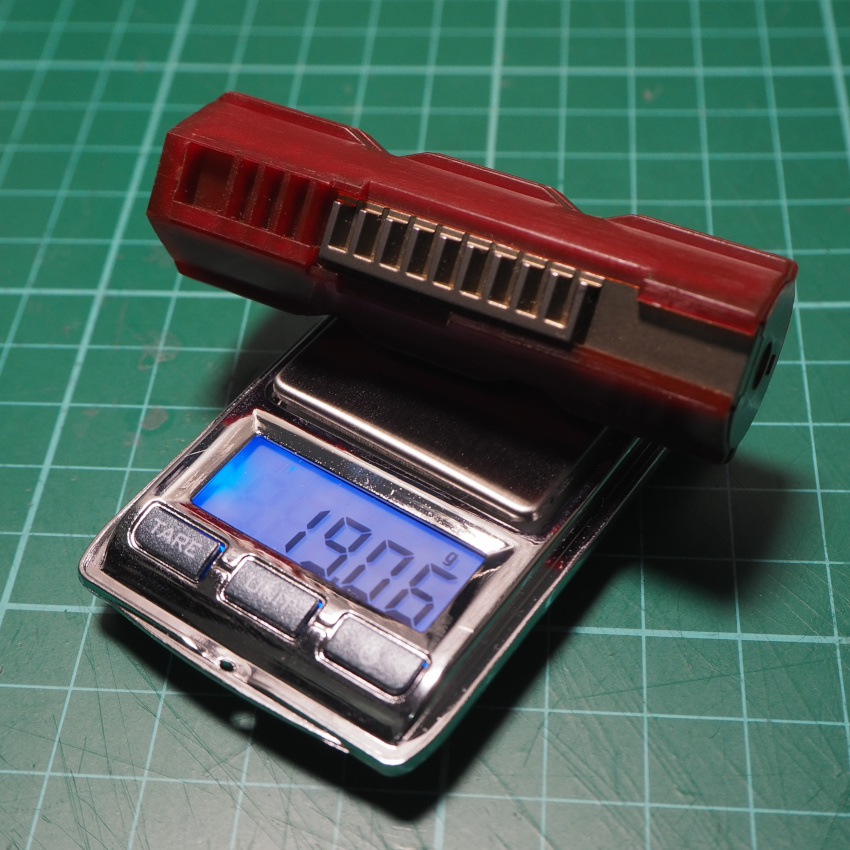

Mass

One notable characteristic of the Lonex Red Extreme Toughness piston is its mass. It weighs in at about 19.06 grams, which is on the heavier side compared to standard SHS pistons that come in at about 13.67 grams. On the other hand, it is significantly lighter than the Combat Union aluminum piston (old generation) that features a heavy metal tooth rack and weighs in at about 23.93 grams.

Conclusions

The Lonex Red Extreme Toughness piston feels hefty and substantial, but not excessively so. The hybrid material transition from plastic to metal teeth is appealing for my style of tech-ing, where I may want to include an engineered point of failure. This isn’t to say that the Lonex Red is not durable. As a matter of fact, the heft of the material and reinforced linked tooth design inspires confidence.

The absence of the second tooth is a nice touch. However, adjustment for the angle of engagement will still require the third tooth to be shaved down slightly. Providing the full third tooth allows you to really shave down only what is required.

It is really great that the Lonex Red piston’s mass falls nicely between light and heavy options. This means that it can be used for a wide range of applications, be it muzzle velocity focused or rate of fire focused.

Unlike other pistons that may encounter trouble as the sector gear teeth travel between the plastic and metal tooth rack, the Lonex Red piston manages a smooth transition. The piston also clears potential obstacles nicely and the fit allows for free movement with little drag.

I will be trying this out inside my ICS M4 S-System under varying conditions. Hopefully it can handle a good amount of beating that its construction suggests.

Afterword

If you like this post and found it helpful, please drop by our YouTube and social channels to say hello! Unfortunately many find airsoft a sensitive topic and are making it increasingly difficult to enjoy and discuss our hobby in more mainstream internet channels. I am going to need your help to grow our community and share the positive aspects of our hobby / sport.

You can help by telling your airsoft buddies about htwarrior.com and sharing blog entries like the one you just read. For those who want to show their support directly, you may consider donating any amount in the PayPal link below. Much appreciated!

Thank you for taking the time to read another Hobby & Tech Warrior post!

– J4