The GP807 is an auto-winding box magazine designed for G&P Laser Company SAW type airsoft replicas. This includes the M249 and MK46 variants. Unfortunately, twice already, the wire insulation for the cable to the winding switch has deteriorated and the capacitors on the controller end up failing. At first I thought the problem might be something complicated, but the repair was simpler than what I assumed.

Design

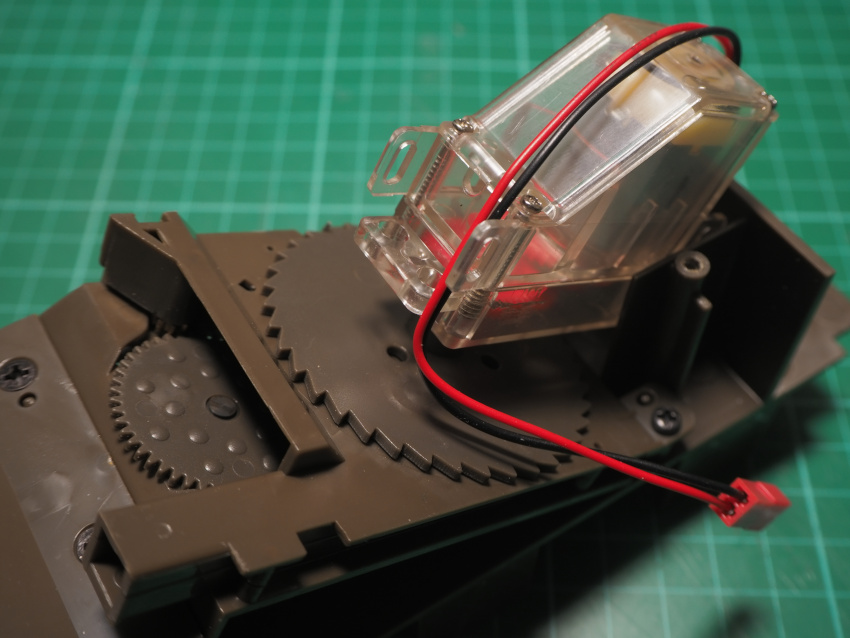

The GP807 features a mini motor and gearbox to run the winding mechanism of the box magazine. A printed circuit board leeches power directly from the leads of the main circuit which activates the winding mechanism in tandem with the trigger pull, or manually via pressure switch.

I’m not much of an electrical engineer, but from what I’m seeing, power is constantly leeching into these control units. Could it be that the circuitry acts as a buck-boost converter that regulates high input DC voltage down and low input DC voltage up?

What Happened

My friend has an MK46 which he asked me to work on. The AEG was really messed up in a lot of ways from factory, but long story short I sorted things out and updated it with a MOSFET. However, at some point the cable for the manual winding switch started to deteriorate and the capacitors on the winding controller on the magazine started to leak. Ultimately we ended up wiring that GP807 box magazine fully manual and bypassed the PCB that wasn’t working correctly.

In relation, I was wondering if the insulation jacket and capacitor failures were somehow related to the TURNIGY 11.1V, 2650 mAh LiPo battery possibly exceeding what this magazine was rated for.

The online web sales page did say the magazine was rated for 8.4V. Later e-mails I sent to authorized distributors claimed that there were no specific limits to the battery that these magazines could handle. Therefore, the problem might lie elsewhere.

What was really frustrating, was that I seem to be the only one experiencing this problem. There was not much that could be found online referencing this experience. To top it off, this happens twice.

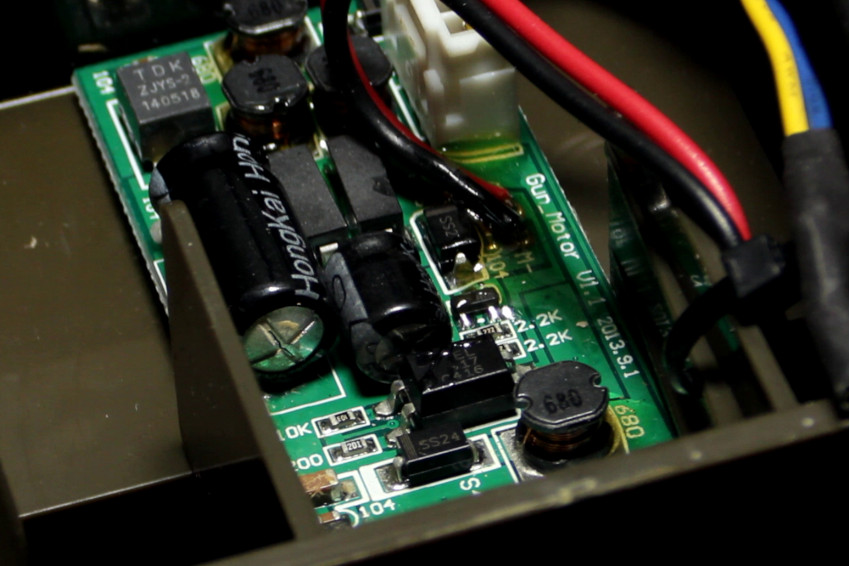

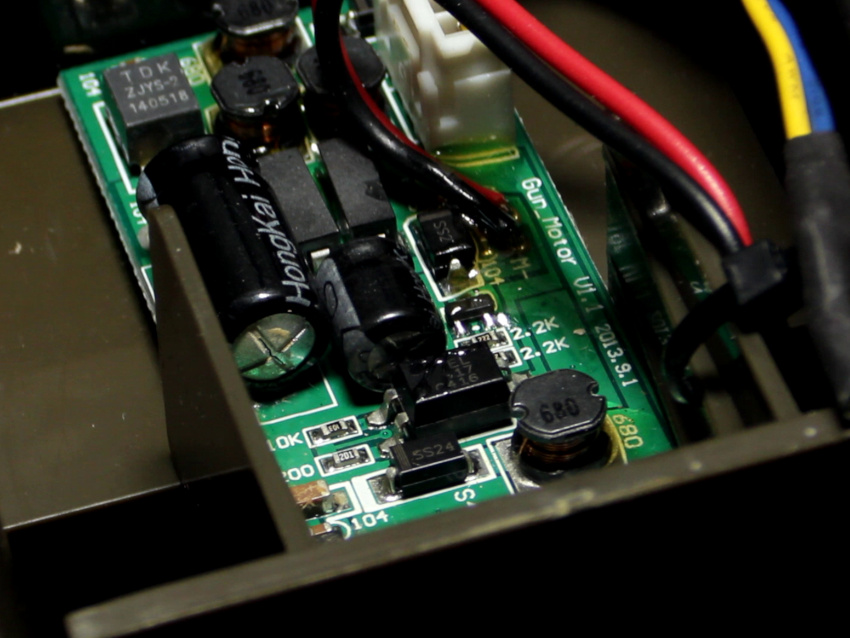

Gun_Motor V1.1

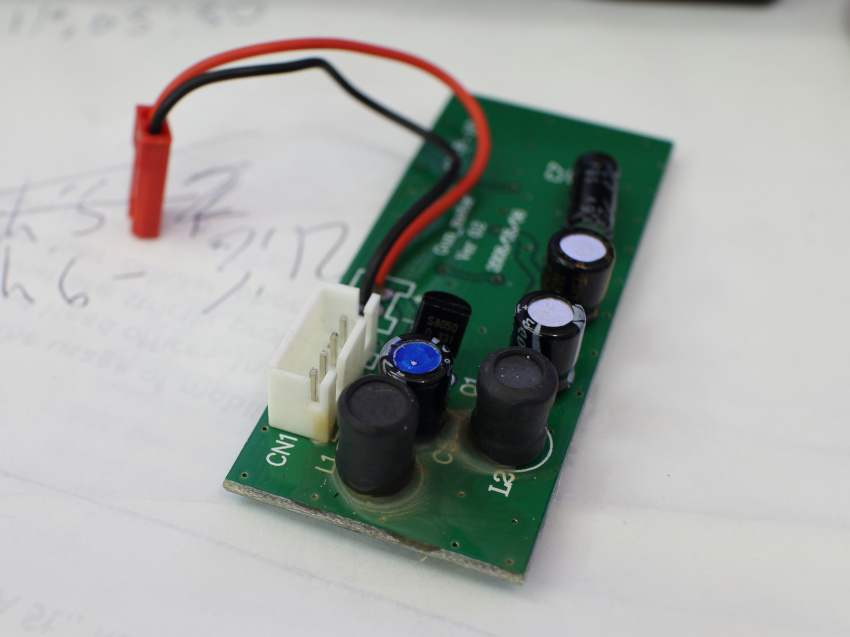

I ordered a new GP807 box magazine as a replacement and it had a revised auto-winding PCB controller that featured surface-mount devices instead of the previous through-hole design. The earlier model was labeled Ver 0.2, dated 2008/05/06 while the V1.1 is dated for the year 2013. This was the first clue.

The same issues manifested on this relatively newer copy as well. The insulation jacket had fallen apart again, and the PCB let out an audible high pitched whine and hiss before the capacitor made a pop and spewed gas out.

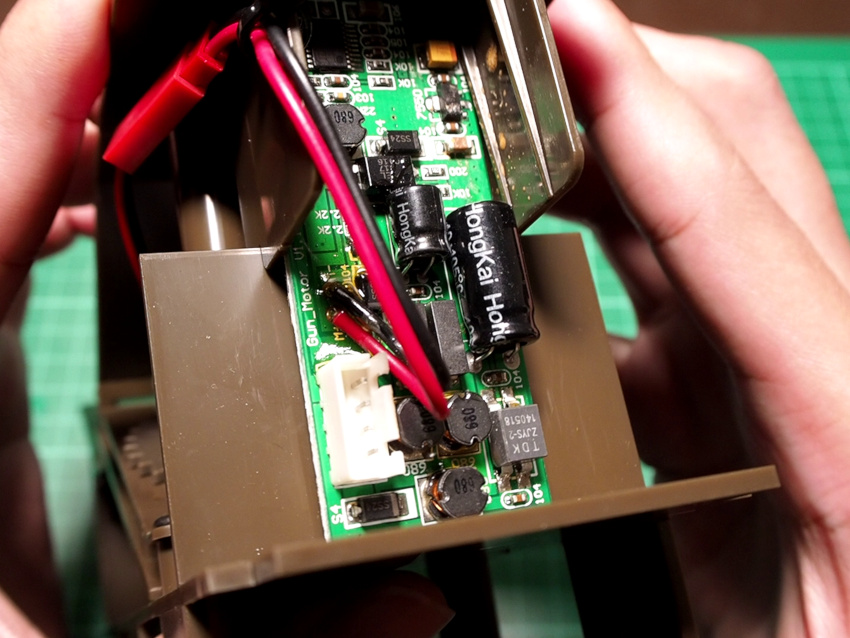

Even though this happened, the magazine continued to behave normally. Just to be certain, I decided to replace the capacitor in hopes the magazine would last longer.

Replacing the Capacitor

As can be seen from the plastic compartment walls and surrounding resistors, splash traces from the venting of the capacitor can be seen.

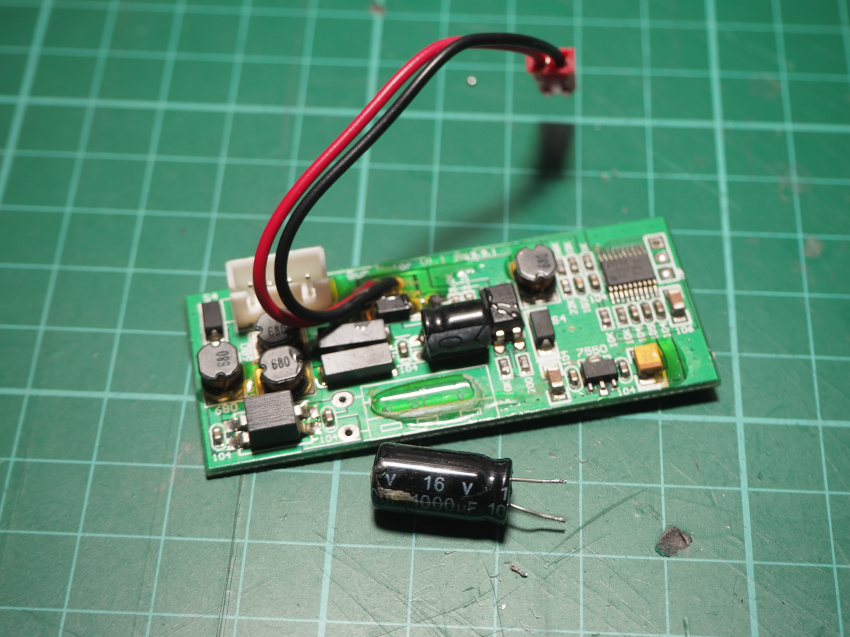

Finding the capacitor technical specs was difficult until it was lifted off of the resin adhesive. It is 16V 1000uF. Finding a replacement under the same exact brand name proved difficult. Web searches for HongKai capacitors brought me results from a video game of the same name.

A quick web search states that causes for capacitors to bloat, leak or explode include: excess voltage, old age, deterioration, or reversal of polarity. Due to the dates marked on the PCBs and the difficulty of finding the HonKai brand, I was under a strong impression that old age of the parts might be the main culprit.

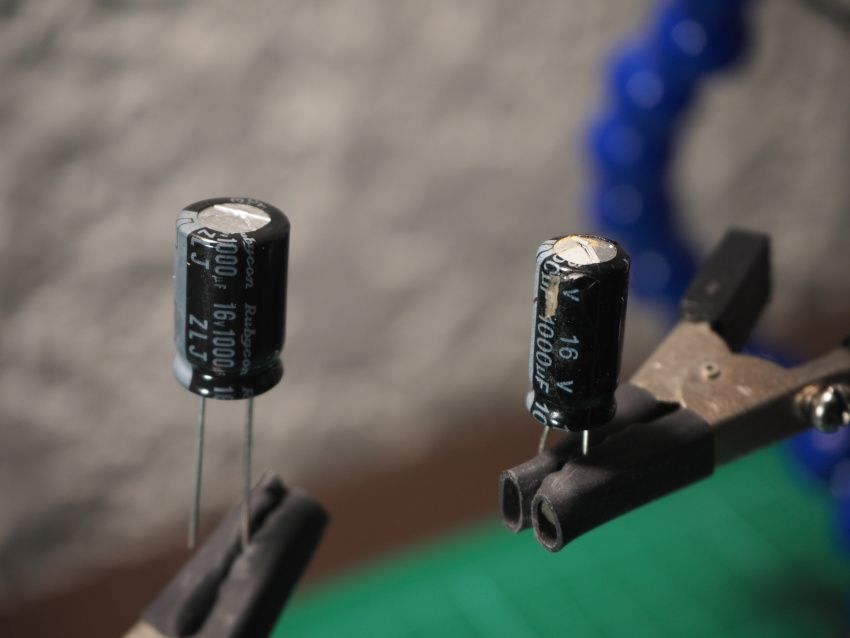

For the new replacement, I went with the Rubycon brand and the ZLJ type. As I understood, ZLJ means the capacitor is aqueous, or has liquid in it. The model I got is known for long endurance and the liquid prevents it from violently blowing up. Instead of violently exploding, failures result in the capacitor venting gas, like the original one.

Side by side comparison shows that the Rubycon equivalent is noticeably bigger.

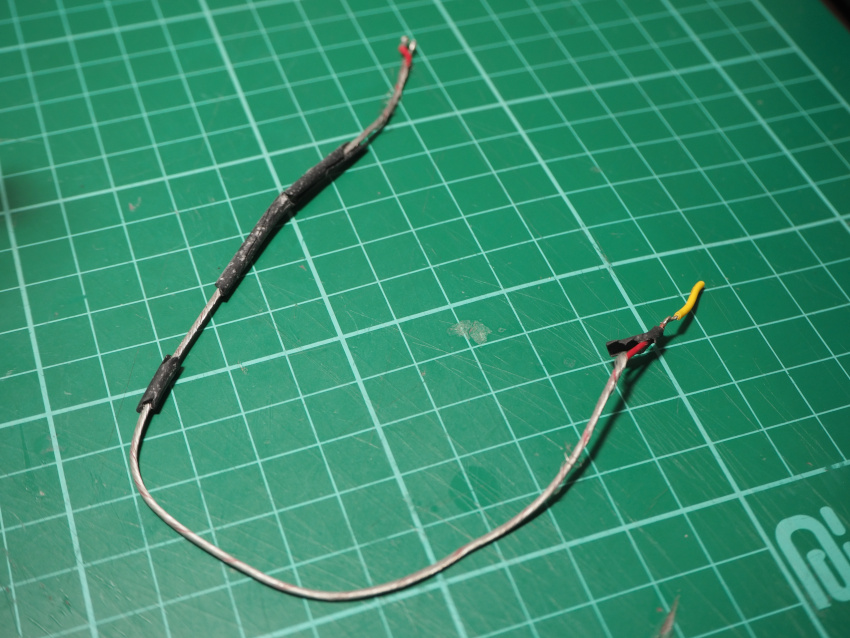

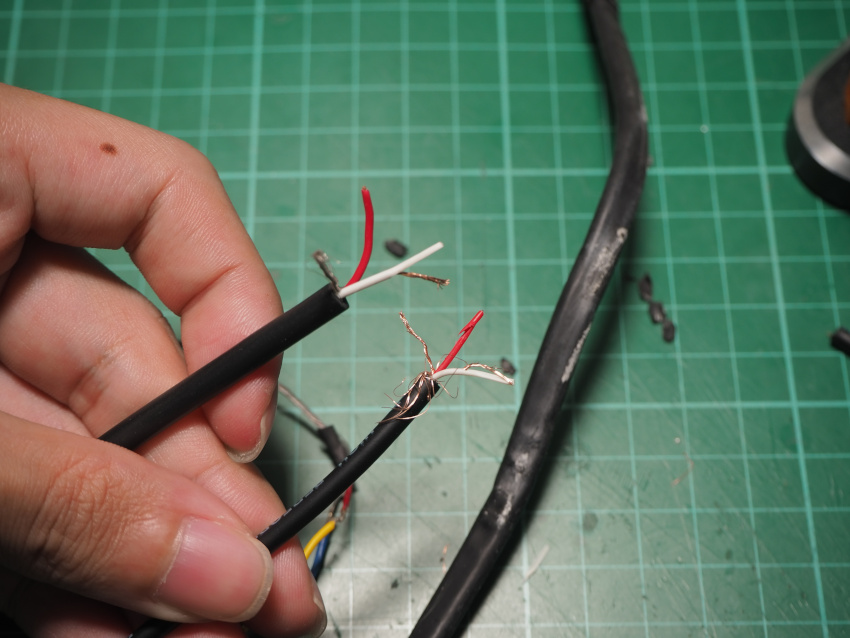

Cable Dry Rot & Replacement

At first I thought that the deterioration of the cable’s insulation might have been related to the capacitor failing and possibly due to its rated limits being exceeded. However I noticed that there was a lot of white powder residue which prompted another web search.

What came up was something called dry rot. High quality rubber is infused with a white stabilizing agent that keeps it from going brittle when exposed to ultraviolet light. Despite this, the insulation of the cable fell apart.

Another search shows that rubber’s longevity can vary from months to years and even decades. It is possible that the insulation on the original switch’s cable may have had a shorter life span.

I don’t recall ever exposing the magazine under direct sunlight so any extreme conditions may have been encountered during factory storage or delivery. In any case, my solution was to replace the old wire with Siamese wire with thicker and more durable insulation.

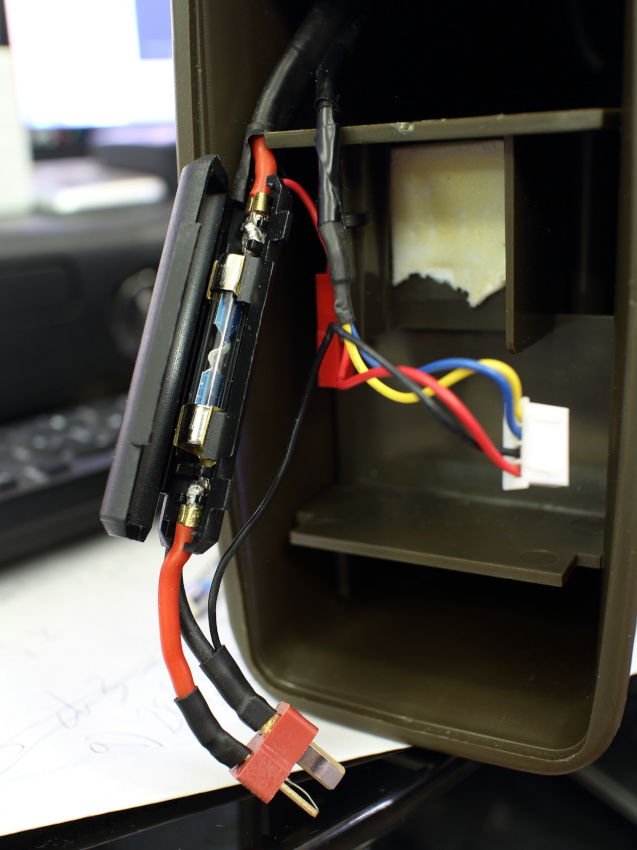

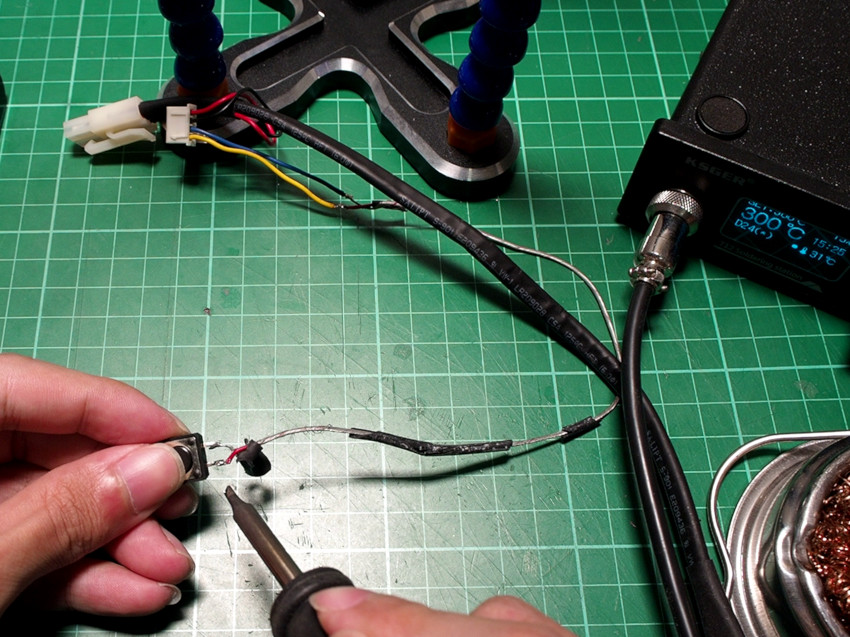

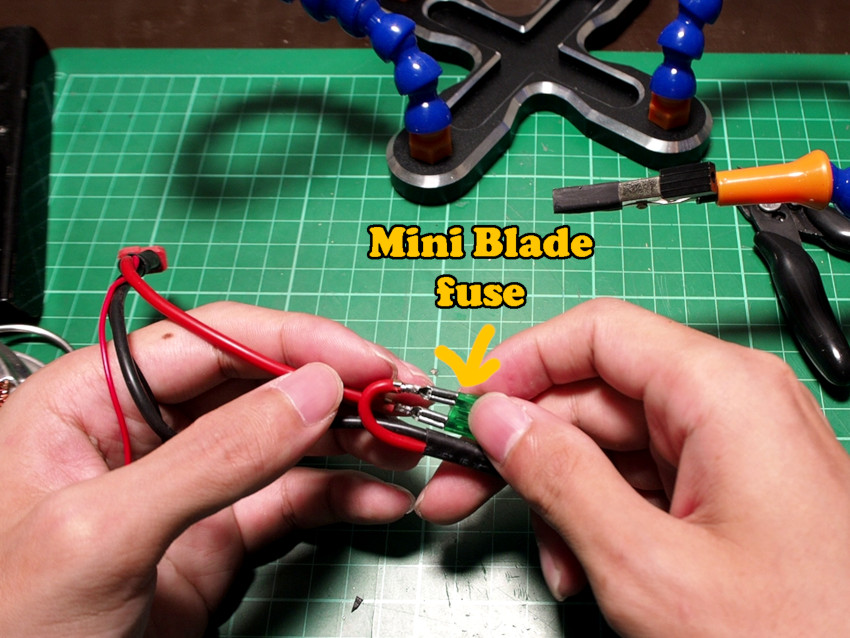

Pro Tip: Adding In-line Fuse

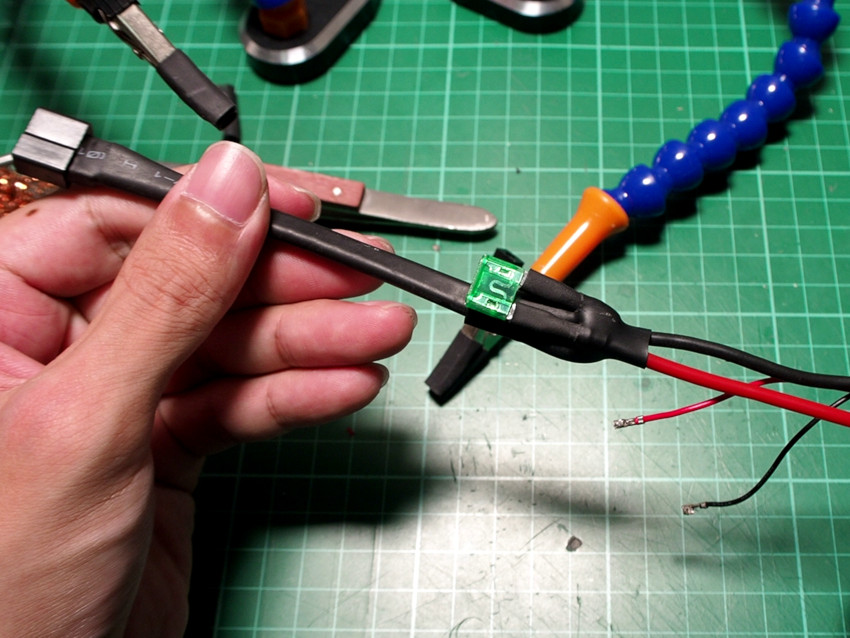

I noticed there was no fuse for the G&P MK46. Even with MOSFETS, I make it a habit to add a fuse to AEG circuits. I like going with mini blade fuses as they are low profile and easier to fit in tight places.

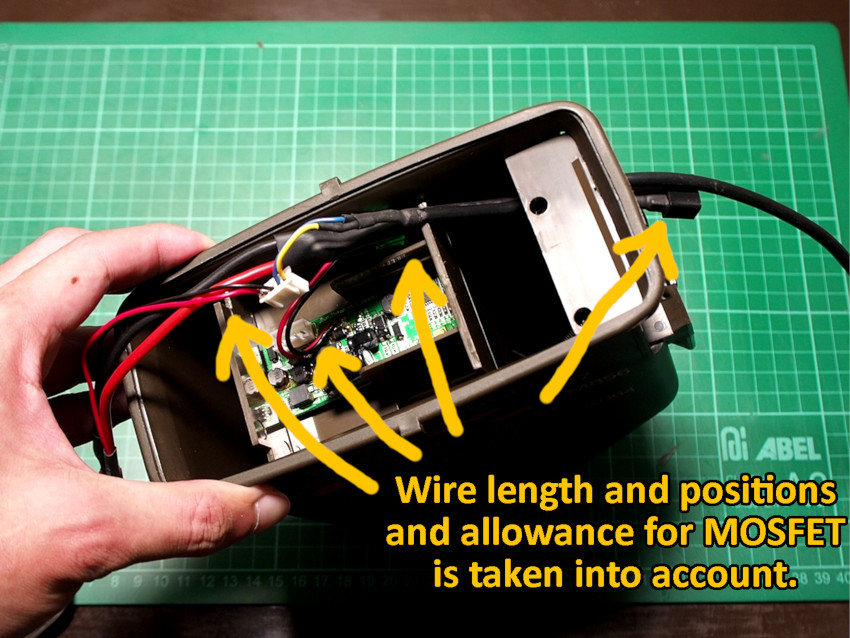

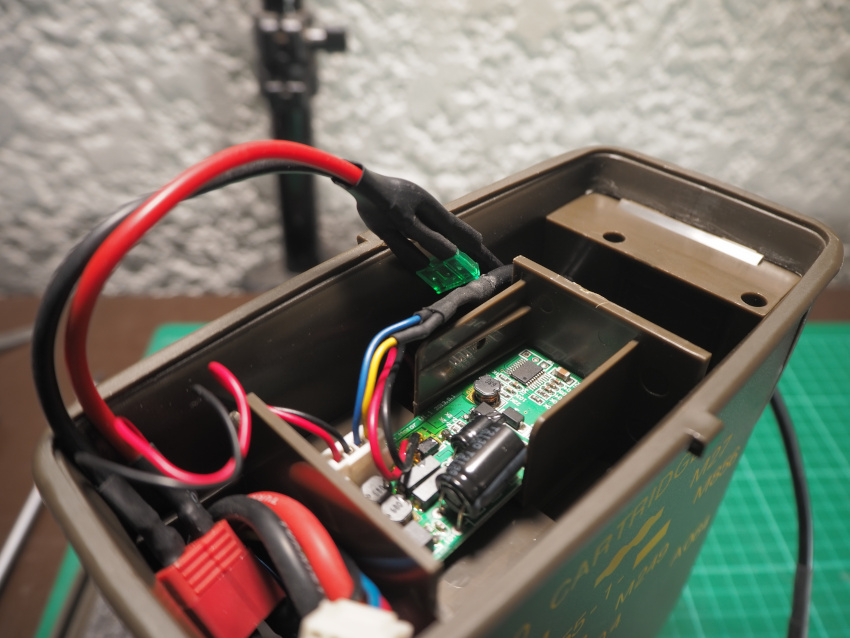

The way I incorporate fuses into my AEG circuits tends to shorten the original length of the wire leads. I had to take note of and mark where I wanted the fuse to be on the wire extension, while making sure it doesn’t interfere with the compartment of the magazine housing.

Conclusion

Age of parts may have very well been the main cause of wire rot and blown capacitors on the G&P GP807 box magazines. It might not be readily apparent when these things are new, but the material most likely deteriorates rapidly over time and don’t last.

As can be seen, the Rubycon capacitors appear to be more robust despite having the exact same specs on the label. The immediate change was the disappearance of the hissing and high pitched noise that came from the PCB when power was plugged in.

As of this time no new signs of failure have manifested. This eliminates my first theory that the power source I was using was overworking the system, or that the circuitry was somehow wired incorrectly.

The only thing left to do now is to get this AEG back into the field and observe for any sign of deterioration to arise again. If problems do appear, my next step is to delve deep into the circuitry design and see if we can play with boost and buck converters to remedy the issue.

However, based on the tests done so far, I am feeling really good about the changes to the wire and capacitor, so I doubt we’d have to mess with this again any time soon.

Afterword

If you liked this post and found it helpful, please drop by our YouTube and social channels to say hello! Unfortunately many find airsoft a sensitive topic and are making it increasingly difficult to enjoy and discuss our hobby in more mainstream internet channels. I am going to need your help to grow our community and share the positive aspects of our hobby / sport.

You can help by telling your airsoft buddies about htwarrior.com and sharing blog entries like the one you just read. For those who want to show their support directly, you may consider donating any amount in the PayPal link below. Much appreciated!

Thank you for taking the time to read another Hobby & Tech Warrior post!

– J4

Can I order pcb board of LMJ..

You would have to contact G&P Laser company if that is possible. I had to buy a new box mag which had the new board.

Ive recently come by your blog and I must say its awesome, specially the airsoft techs analisys. Thanks a lot mate.

Thanks for the kind words Gabriel. I’m elated at the positive feedback.