There are many different airsoft manufacturers that often develop and release a similar platform. One of the issues they face is gaining aftermarket support. Sometimes a unit you really want does not come from the manufacturer with the best aftermarket support. By the time the WE F226 was announced, there were already multiple 226 platforms on the market. In this blog post I strip down a WE F226 and a Tokyo Marui P226 to compare their parts in hopes of finding similarities and therefore aftermarket options.

Intro

To help facilitate the answer to this question, I went through the liberty of dismantling my WE and Tokyo Marui 226 to compare them against each other. Tokyo Marui is the gold standard in the airsoft industry when it comes to the garnering aftermarket support. For a long time they were at the forefront of innovation and provided the initial designs by which the rest of the manufacturers based their own releases off of. By comparing Tokyo Marui part fitment directly onto the WE F226, it may be possible to identify aftermarket parts that will have high compatibility.

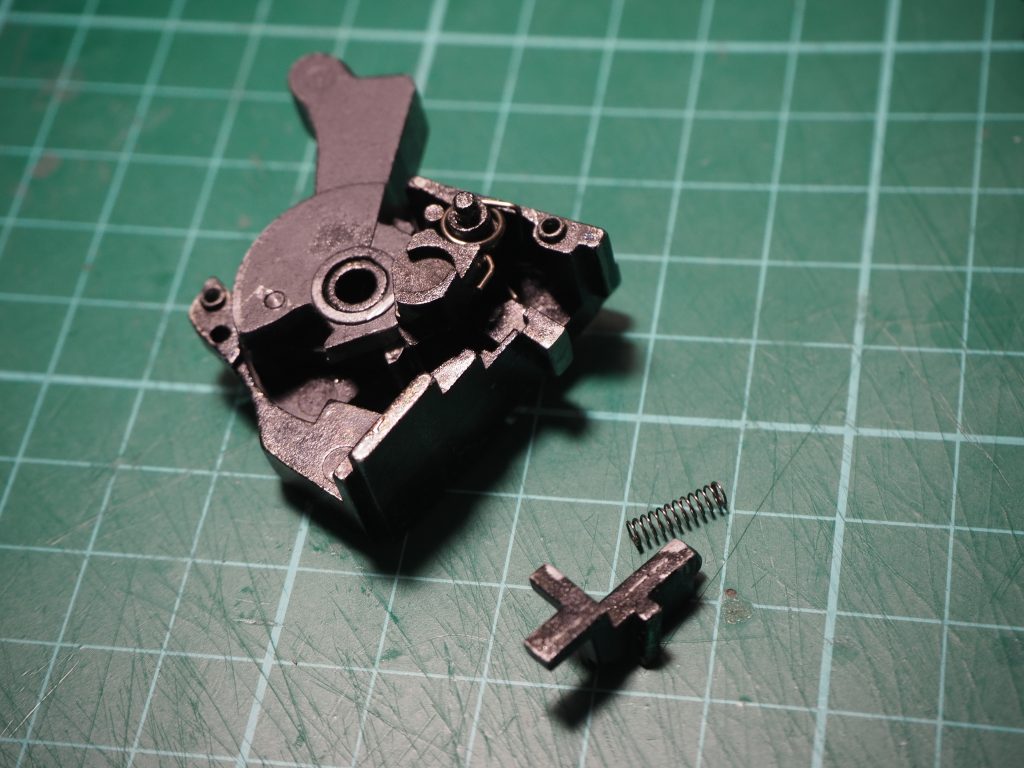

Furniture

Grip panels and screws are an important aesthetic option in my opinion. My first ever airsoft GBB was a Tokyo Marui Tactical Master. The M9 is a stylish gun design and I remember spending hours looking through wood grip panels and stainless grip screws online. When disassembling both the WE and Tokyo Marui 226, there is a clear difference that can be seen between how the hammer spring strut is secured. The Tokyo Marui features a removable block captures the strut and hammer spring, while the WE has a narrow channel molded onto the lower frame. A pin keeps the strut on the WE in place.

The second difference is that the Tokyo Marui grip panels have 2 more pins that link them together. Despite these differences the cavities in the WE and Tokyo Marui 226 grip panels they are interchangeable between each other. The grip screws that secure the panels onto the lower frames are interchangeable as well.

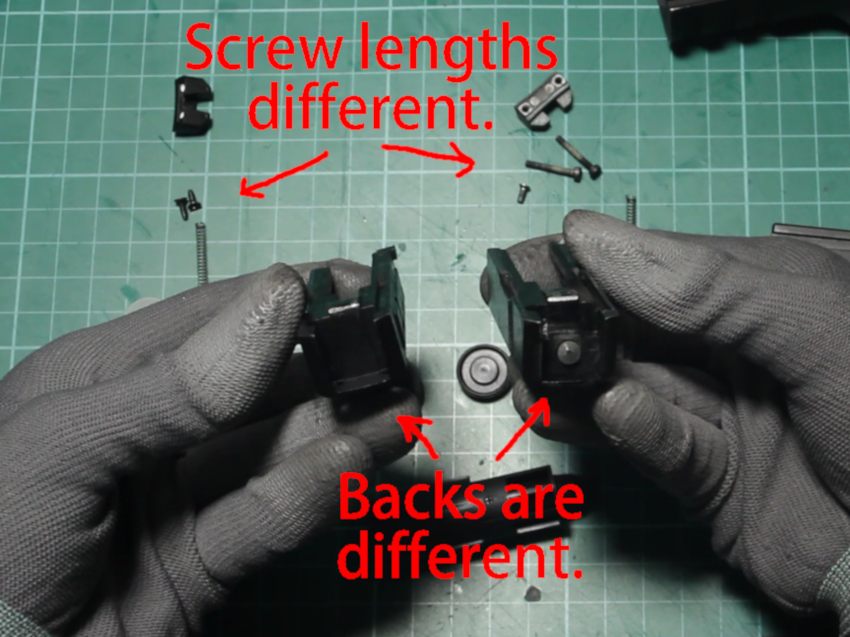

Rear Sight

The WE blow back housing features an extra block with fake firing pin out of the box. This adds considerable length to the screws required to secure it to the slide and rear slide. In the photo below, the Tokyo Marui set of parts are shown to the left. The rear sights are very similar. However the screws are slightly narrower and much shorter.

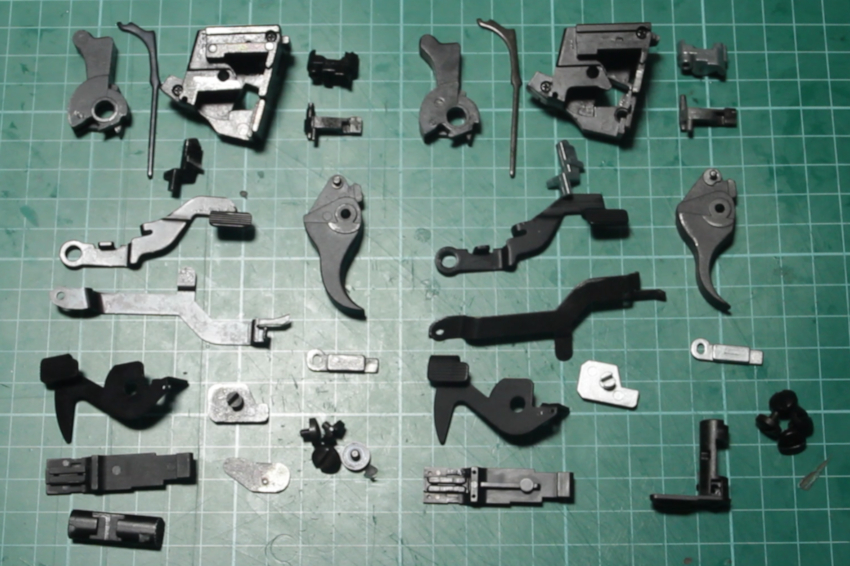

Controls

The main controls on a 226 platform are the hammer, trigger, de-cocking lever, and magazine release. So far these components on the WE have held up well to wear and tear. There is a bit of wear on the finish of the hammer and magazine release, but it is very minor. As they are, the hammer, trigger, and de-cocking lever are readily interchangeable between WE and Tokyo Marui platforms without issue. The trigger bar spring on the Tokyo Marui is frame specific but can be straightened out to fit on the WE. More on this is taken up in the video provided.

The Tokyo Marui magazine release also happens to be a little too large to slip into the WE lower frame. Some sanding could help with this issue. Also the magazine release spring on the Tokyo Marui is a little wider than that on the WE

The default take down lever on the WE eventually broke from the F226’s recoil. In this case, I have already swapped it out for a Tokyo Marui spec steel aftermarket part from Guarder and it fits and functions perfectly. Aftermarket spring guide rods and spring made for the Tokyo Marui version also work. Overall, thanks to the interchangeability of these parts, WE F226 also enjoys aftermarket part choices to dress up the main controls.

Hop Up Chamber

The hop up chambers between manufacturers are not readily compatible between each other. This is due to the varying sizes between the channels on the locking blocks as well as the lug rails on the chambers themselves.

WE seems to have a narrower channel on the locking block and smaller width lugs on the chamber. When trying to fit a Tokyo Marui or KJW chamber, the larger sized lugs on the chambers prevent them from entering the channel or seating all the way back on the locking block.

Although the direct aftermarket chamber part support for WE F226 is low, I believe that with some modification reshaping the lug rails on the Tokyo Marui and KJW chambers will allow them to seat into the WE locking block. However, like with most fitment alterations, care must be taken to ensure proper seating and alignment. In addition, hop up packing, dials and arms are completely interchangeable and will improve the WE’s performance without the need for swapping out the whole chamber. Info on this can be found in this blog post.

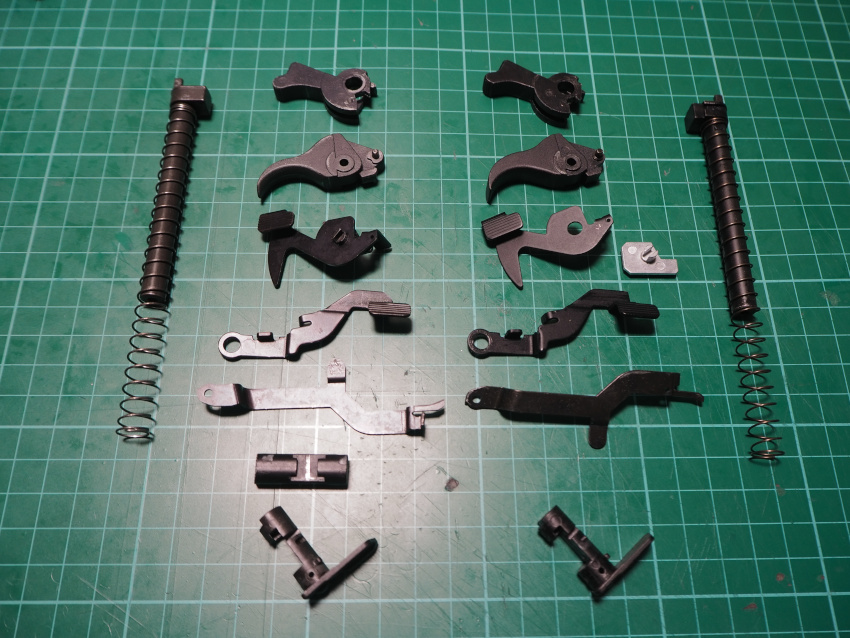

Internals

The main internal parts of a GBB are the blowback housing, nozzle, valve, valve knocker, and sears. Unfortunately, although the WE and Tokyo Marui blowback housing are similar, they do not share the same dimensions and are not interchangeable. Furthermore the nozzles themselves are also different in size with the WE being larger at 15mm in internal diameter.

Thankfully the valves in the nozzles, where most of the tuning can be done, manages to be virtually interchangeable. Also, the sears and valve knocker as well as springs that make up the action are 100% compatible. Interchangeability between these parts will help greatly with the WE F226 aftermarket parts support when it comes to servicing and operational longevity.

Slide & Frame

The slide and frame of the Tokyo Marui P226 is made of plastic which is light and helps with snappy recoil response. However, if one decided to run higher pressure gas instead of the recommended ‘134a duster gas’, the Tokyo Marui slide and frame will eventually break. What makes the WE a compelling choice is that the slide and lower frame are constructed from aluminum and can therefore handle stronger gas.

One reason you may want to stick a WE locking block into a Tokyo Marui style frame would be to take advantage of the many varying styles available. Unfortunately for WE, the locking block and rear chassis does not sit readily into the Tokyo Marui frame.

The locking block sits too high due to excess material and interference. The rear chassis that houses the hammer, sears, and valve knocker also have alignment issues when it comes to the location of the pin holes that will help secure them. Despite the differences, the assemblies sat relatively close to the correct positions.

With enough care, it may be possible to seat these assemblies into a Tokyo Marui frame. It will require trial and error as well as a slow careful attempt to ensure the frame fit and alignments are not ruined.

Magazine

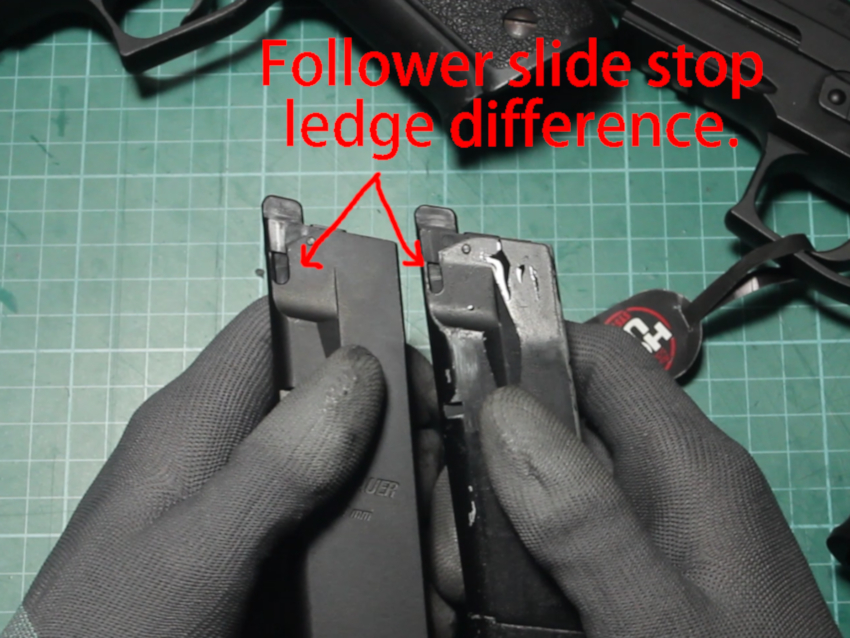

For all intents and purposes, both WE and Tokyo Marui 226 magazines will cycle both GBBs. However, the part on the WE follower that catches the slide stop sits lower and doesn’t push it up high enough on a Tokyo Marui 226 and prevents it from locking the slide back on empty.

Conclusion

By disassembling and comparing a Tokyo Marui P226 we were able to identify potential compatible WE F226 aftermarket parts. Because of this the WE F226 remains as a strong budget option. Despite the good compatibility, there are also numerous parts that are not readily or are not completely compatible without some modification. Key dress up parts in the form of the main controls, trigger, hammer, magazine, slide release, and de-cocking lever are compatible. Important internals like the nozzle valve, magazine valve knocker, and sears are also fully upgradeable with parts made for the Tokyo Marui P226. Full metal frame kits might pose a bit of a fitment challenge but is not impossible.

However even without an easily adaptable metal body kit, the stock WE aluminum slide and frame are already nicely made. If there was one complaint I would say it would be with how the tip of the metal WE outer barrel was shaped, which was not as elegant as the Tokyo Marui’s. Overall, I am inclined to recommend this airsoft sidearm as long as the individual is willing to deal with some minor resolvable quirks.

Afterword

If you liked this post and found it helpful, please drop by our YouTube and social channels to say hello! Unfortunately many find airsoft a sensitive topic and are making it increasingly difficult to enjoy and discuss our hobby in more mainstream internet channels. I am going to need your help to grow our community and share the positive aspects of our hobby / sport.

You can help by telling your airsoft buddies about htwarrior.com and sharing blog entries like the one you just read. For those who want to show their support directly, you may consider donating any amount in the PayPal link below. Much appreciated!

Thank you for taking the time to read another Hobby & Tech Warrior post!

– J4

Nice Post, I’ve built a p226 steel slide using we lower, little bit of messing nozzle etc but great, spot on weight to real steel

That’s great! How did you manage to mate the hop chamber to the lower WE frame?

Hey man, I noticed u r still active on this site, I recently disassembled my KSC USP Tactical S7 and I couldn’t assemble it back, Could you possibly guide me with this?

Sorry for the late response. Did you manage to get it back together? Which part of the reassembly process are you having trouble with?