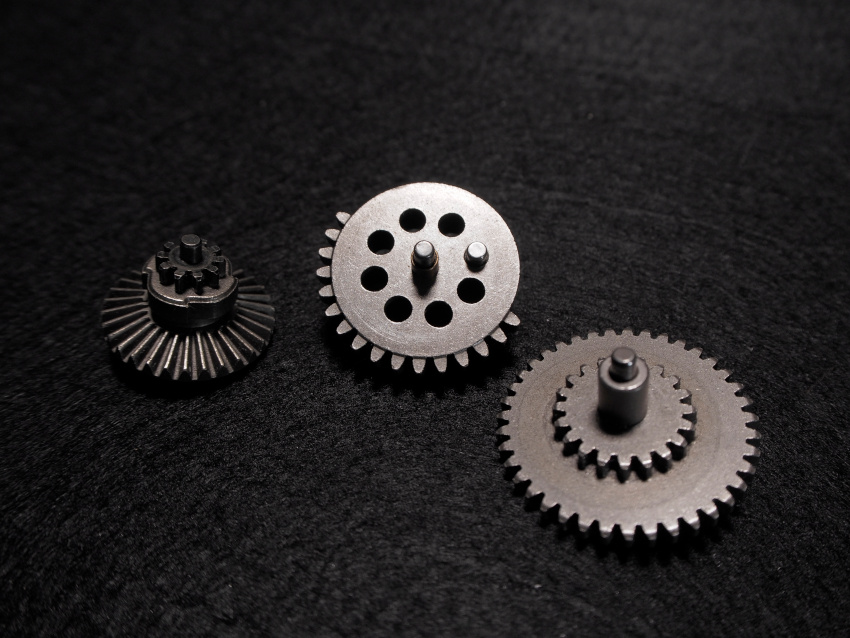

Airsoft gear sets transfer rotations from the motor to pull on the piston assembly during a compression cycle. They can come in any number of pieces depending on the kind of gearbox. The most common set includes a bevel gear, sector gear, and spur gear.

The bevel gear is the gear that transfers power from the motor and pinion gear. It also has separate profiled teeth for the anti reversal latch to catch on to.

The sector gear only has teeth on part of its circumference, the number of which corresponds to the number of teeth on the piston body’s tooth rack. These teeth will pull the piston and spring back and release it where they end.

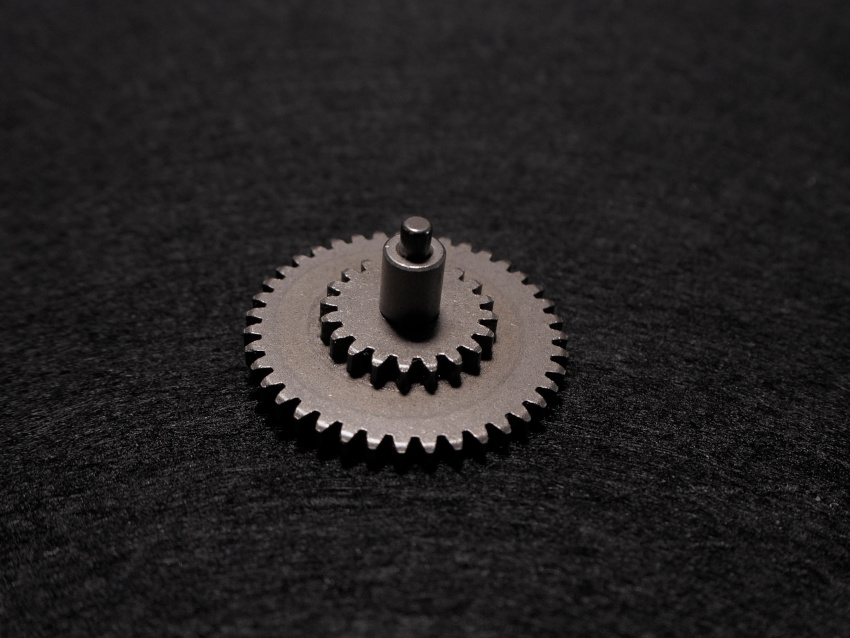

The spur gear acts as the intermediary gear between the bevel and sector gear. There can be more than one spur gear depending on the design.

Pinion gears on the motor are part of the gear train, but are usually not part of the set.

Gear Ratios

There are different gear ratios available. The ratio can either be low speed high torque, or high speed low torque. It used to be that the main factor that determined the choice of gear set depended on the weight of the main spring.

High muzzle energy builds required the high torque nature of high ratio gear sets to pull heavy main springs. High rate of fire builds required the high top speed of low ratio gear sets when paired with lighter main springs. The core principles behind these two concepts still hold true today. However, builds are no longer strictly confined to these conventions. This is thanks to the introduction of battery, motor, and electronic control advancements.

Ratios come in various ratios, from a low 10:1 all the way to a high 42:1. The ratio means how many motor revolutions it takes to rotate the sector gear and cycle the piston one time.

Multi Sector Gears

However, there is an exception when it comes to multi sector gears. Multi sector gears cycles the piston multiple times per one complete revolution. They do this by grouping separate sets of teeth along the gear’s circumference which pull on the piston each time a set of teeth passes.

The multiplicity of cycles per revolution is great for rate of fire, but it comes at the cost of the stroke’s length. The shorter stroke length results in lower air volume to work with which can only be compensated with by increasing the weight of the main spring.

Multi sector gears first came in the form of the Dual Sector Gear by RiotSC, and then followed by Maekii’s Triple Sector Gear.

Straight or Helical Gear Teeth

The main advantage of helical teeth profiles is a change in sound signature. In automotive applications they significantly reduce gear noise. In airsoft this is especially true with the Lonex Spiral Bevel & Pinion Gear replacement which cuts much of the high frequency noise even when paired with straight cut gear sets. This makes gearbox operation sound more like a crunch than a screech.